After Day 20: Adventures in 3D Printing for Beginners - A Total Meltdown with major layer adhesion issues coming out of the blue, I took a break for a half-a-day. In my sleep, I decided the best way to begin to isolate this new rouge layer adhesion problem was to install a different slicer and print using a totally different software environment. If the print still has layer adhesion issues, we know it is a hardware issue. If the print turns out good, we will learn it is more-than-likely an issue with the slicer I have been using, Cura (maybe some setting, configuration or update issue).

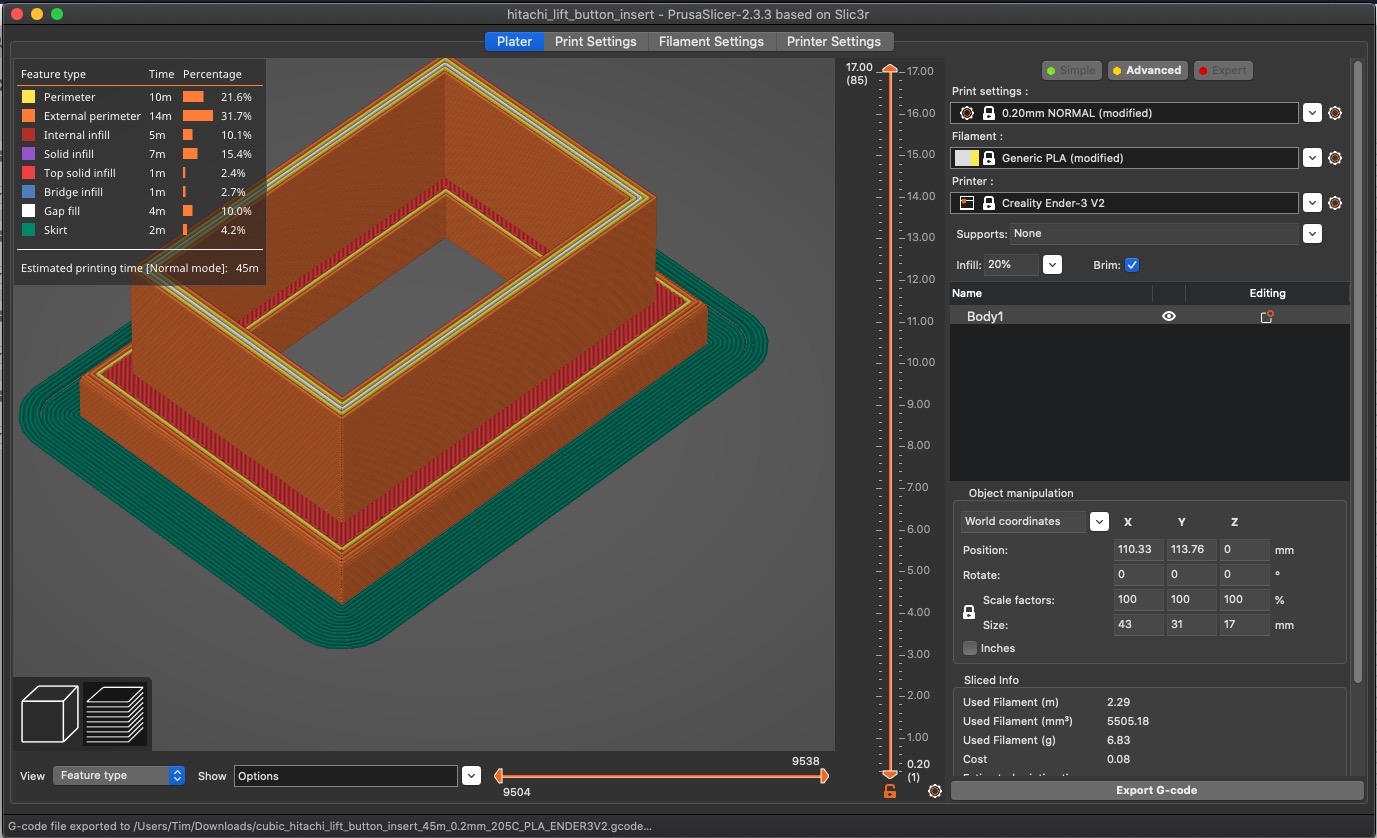

I decided to go with the https://www.prusa3d.com/prusaslicer/ for macOS based on Slic3r, because I could not get Slic3r to install and run on my 64-bit macOS. I installed the Prusa slicer, and the slicer installed easy enough on macOS; and followed the initial setup

When I went to print using Prusa, I noticed that I could only export a GCODE file and not print directly to my printer. A little research showed that Prusa wants us to use printer software from https://www.pronterface.com/ but this printer package complained I was on 64 bit machine and the PronterFace software only works on 32 bits (at the time of this post).

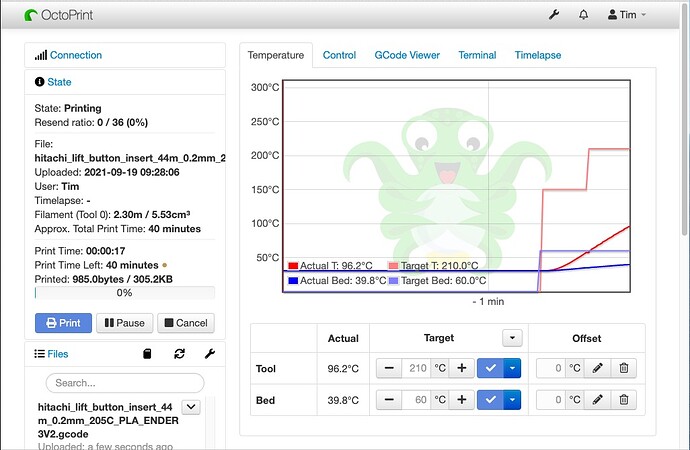

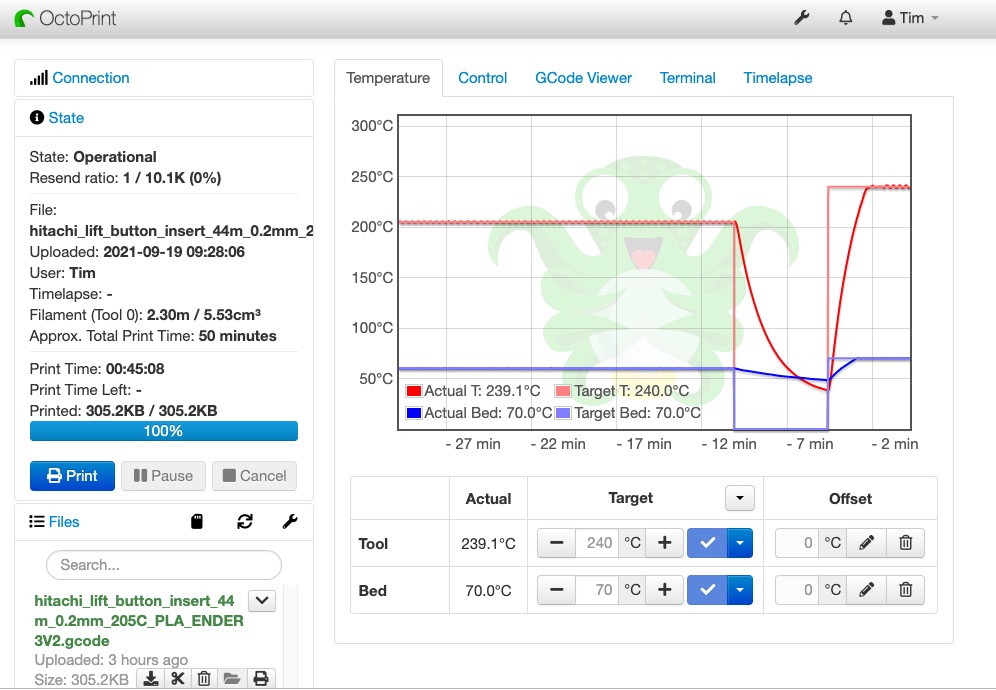

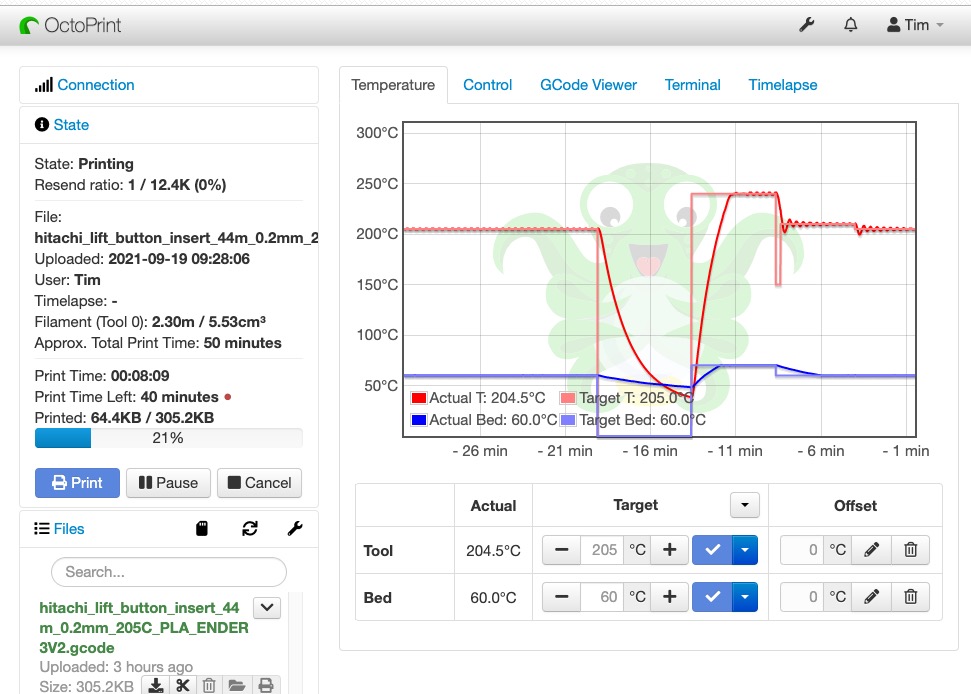

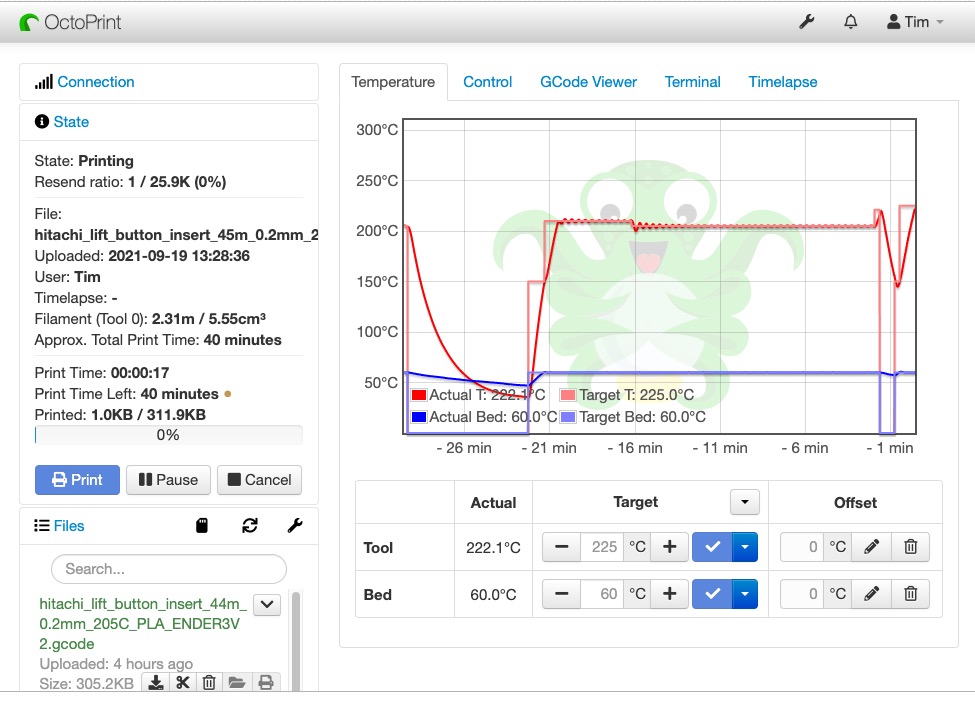

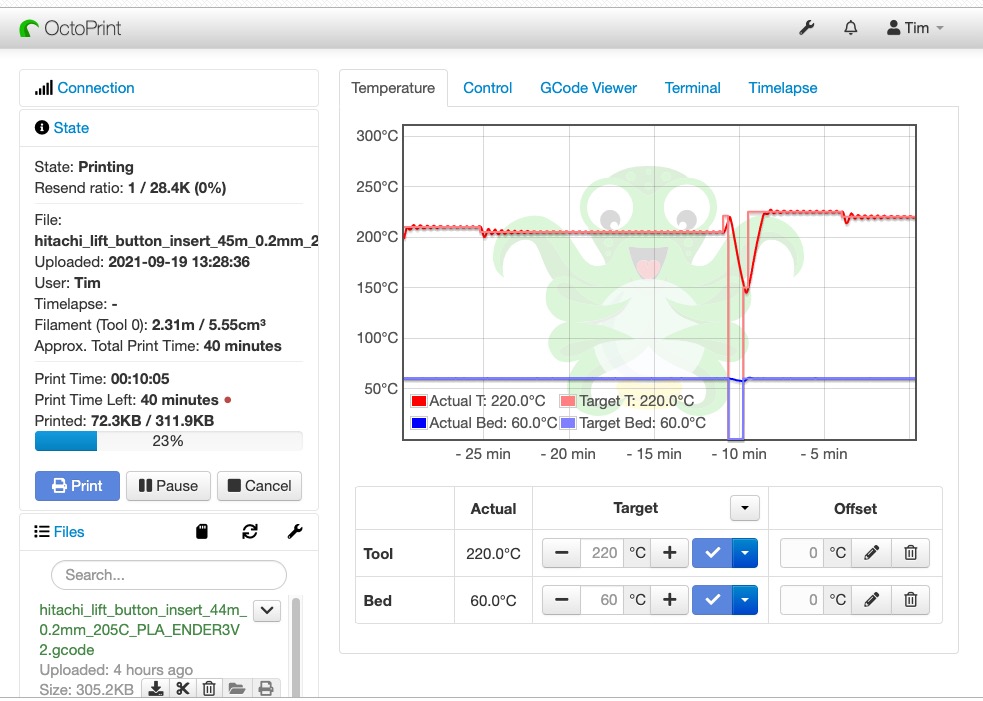

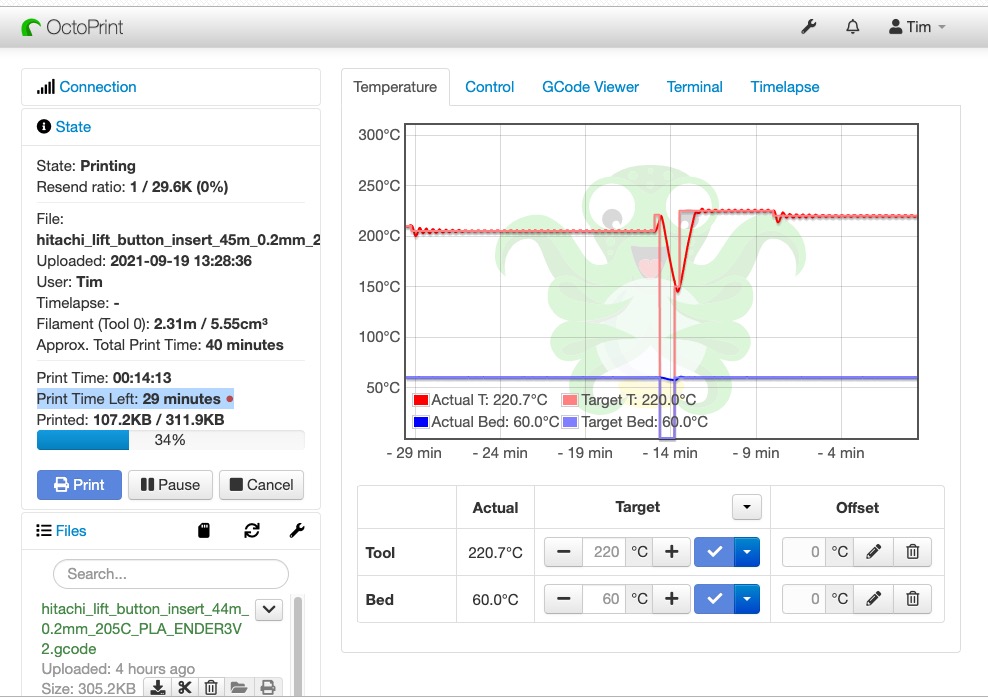

After that, I decided to installed OctoPrint, https://octoprint.org/, a Python-based 3D printer very popular with DIYers and 3D print-farmers. I followed the tutorial Setting up OctoPrint on MacOS and after updating Python and setting up all the basics, OctoPrint was up and running:

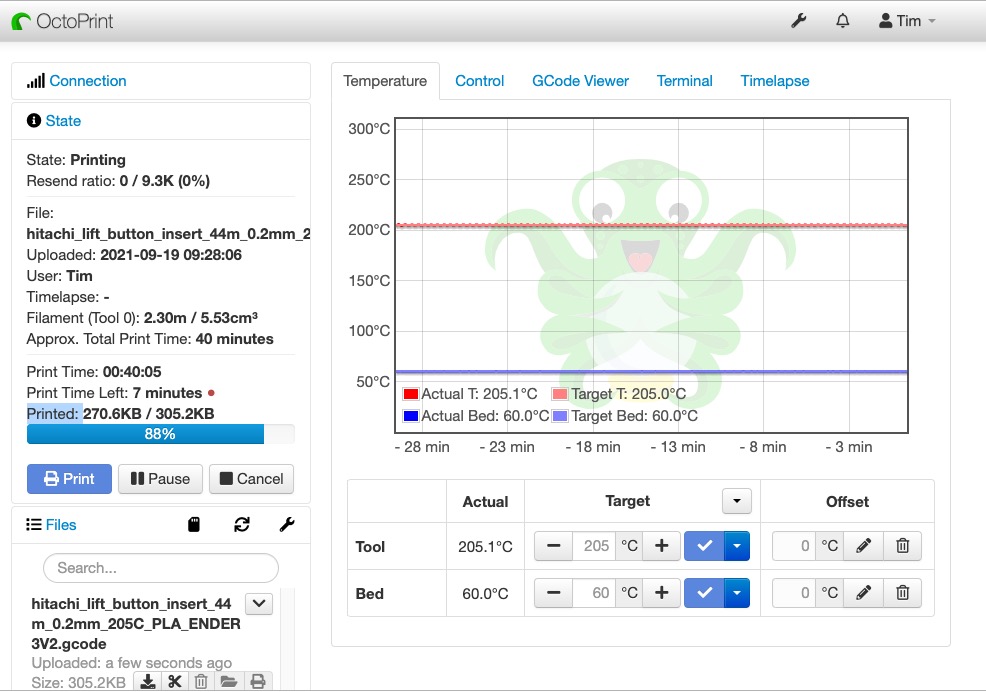

At this moment in the space-time continuum, there is 14 minutes left until this test print with new slicer software and and a new printer software is done:

My first impression with the Prusa slicer is very good and I'm going to stick with the Prusa slicer for now. I like the dark mode (which Cura does not have) and the zoom function (camera perspective) works better than with Cura. Cura is still very good, do not get me wrong. However, the Prusa slicer is looking promising because of dark mode and the nicer zoom.

My first impression with OctoPrint is that this is truly a "community-based" Python application and it is a lot more time-consuming to install and get OctoPrint running than the very slick Cura slicer (which also can print), but on the other hand, I like the web-based interface and the "in your face" bare-bones DIYish control and the ability to add a webcam to OctoPrint to keep an eye on prints remotely. It looks like OctoPrint will give a DIYer a lot more control over the details of the actual print process and this can only be good, right? After all, I'm now three weeks into this new "3D Printing Mania" project, having already printed nearly 1KM (3KG) of filament so far; and so I am not really a complete noob at this point, am I?

Sidebar: My wife is actually glad the printer has problems so she does not have to compete for my time with 3D printing 24 hours a day!

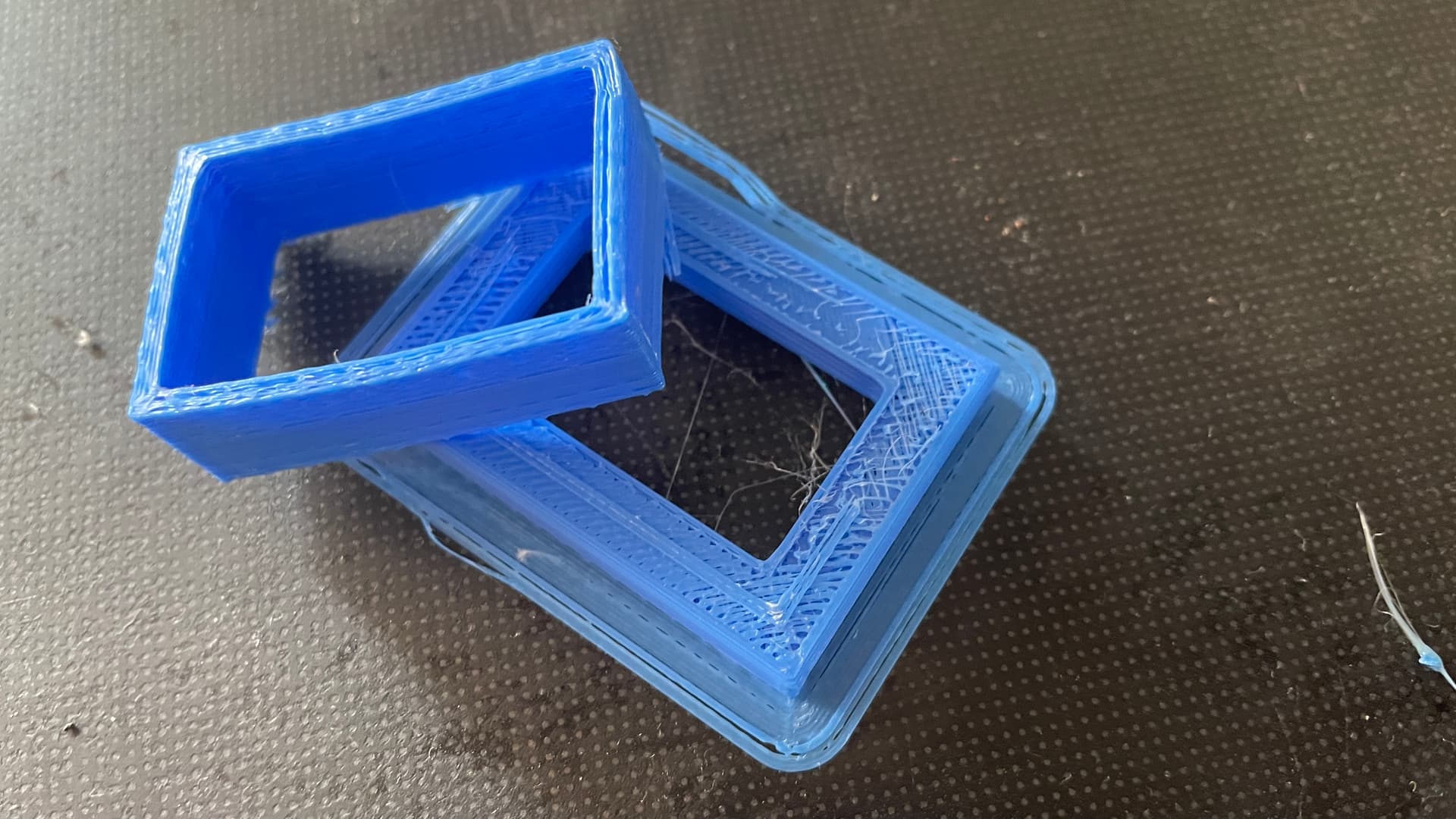

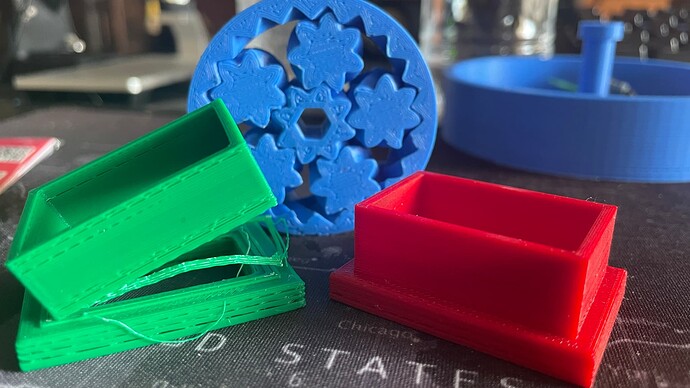

With only a few minutes until touchdown on this test print, things do not look good. As you can see from this quick picture "on the bed" we can see the same layer adhesion problem from Day 20:

We are now close to T minus 7 minutes for this test print, and as the quick peek above shows, the layer adhesion does not look promising, and I'm thinking there is definitely a hardware issue with my 21 day old Ender3 V2, I'm guessing there is some clogging in the extrusion tube or extruder.

Should I be doing this analysis on YouTube, or just keep the analysis raw like this in a forum? I think it does not matter if I post here or on YT. I have few YT followers on my YT channel and making videos takes a lot of time. I'm not interested in wasting precision time making videos when it's easier to just do the analysis live in our community forum.

Sidebar: For all those who love making YT videos, you have my admiration because I know how much work making videos can be; and it takes a great deal more time to make a video ready for YT than it does to actual do the work for sure. I prefer doing the work and not spend time making videos. My bad, I know.

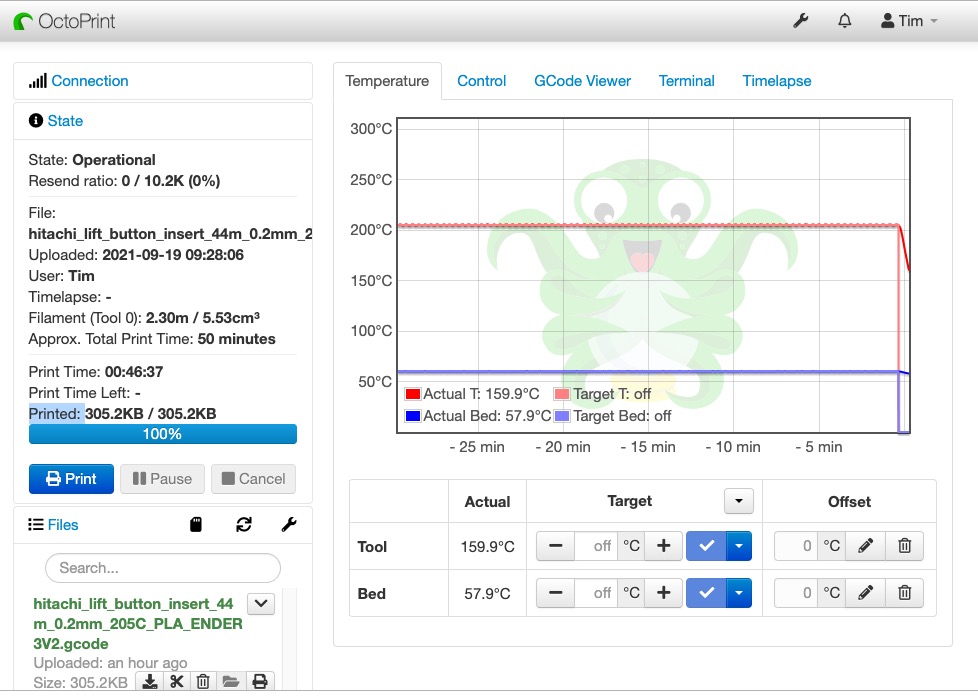

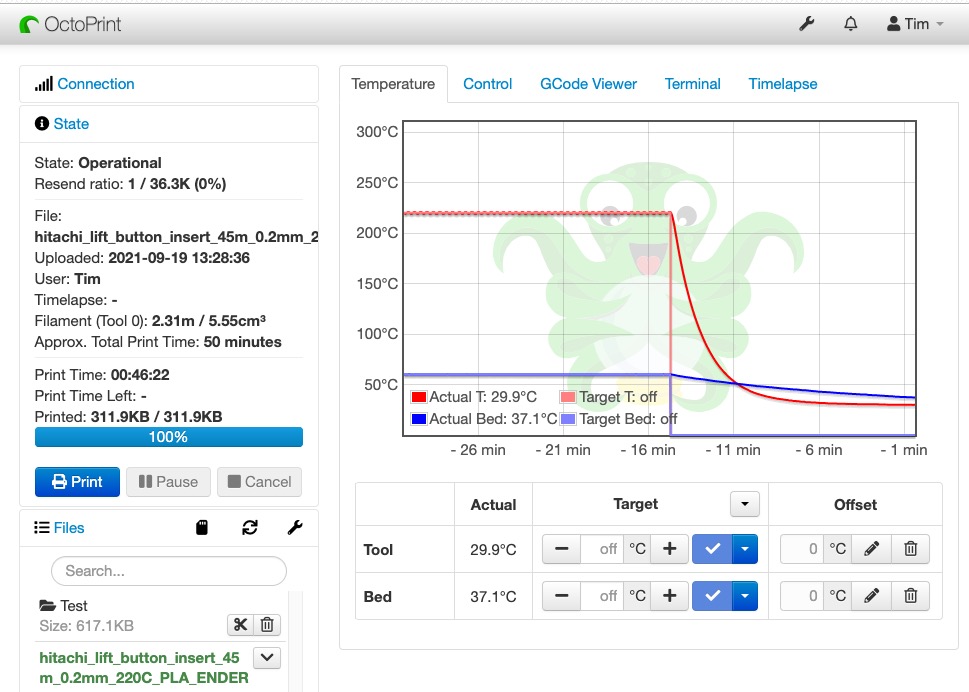

The test print is done!

The results are basically the same, bad layer adhesion, so I think we can safely conclude this layer adhesion issue is a hardware issue and not a software issue. We get the same results (poor layer adhesion) with both software setups:

- Cura slicer (with built in printer)

- Prusa slicer with OctoPrint

This "new software" test print fell apart just trying to pull the print off the bed:

The good news is that I have installed the Prusa slicer, which I like; and also OctoPrint, which is interesting.

Also, we now know to a strong degree of certainty that the issue is more-than-likely related to hardware and "just changing the nozzle" yesterday did not solve this Day 20 problem with layer adhesion. This is just a wild guess, but I'm guessing my switch from PLA to PETG and back to PLA may have caused the clogging, but I could be wrong.

With the super popularity of 3D printing and video tutorials on every aspect of this topic, I have not actually seen any video tutorial or post which has gone into this level of detail and analysis on an actual printing problem. I hope this "live blog" is useful to other makers, especially beginners to 3D printing.

Next, I need to disassemble the extruder and look for clogs or flaws; and to be honest "clogging" was not on my list of the top 10 reasons to love 3D printing!

That's all for now.

See also: