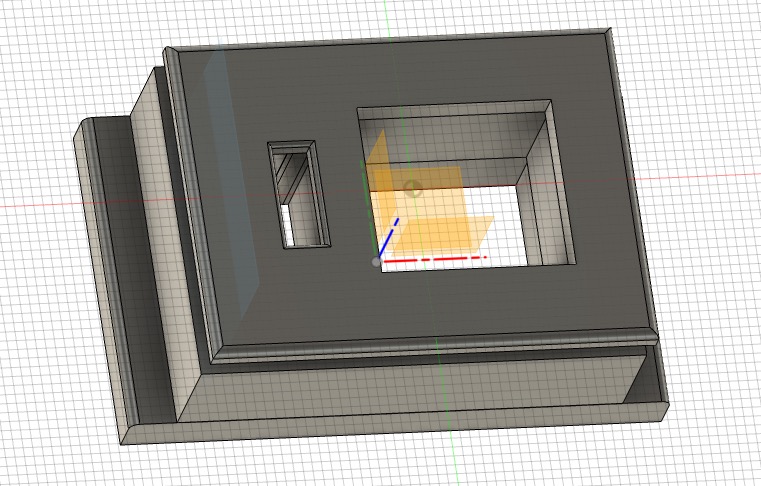

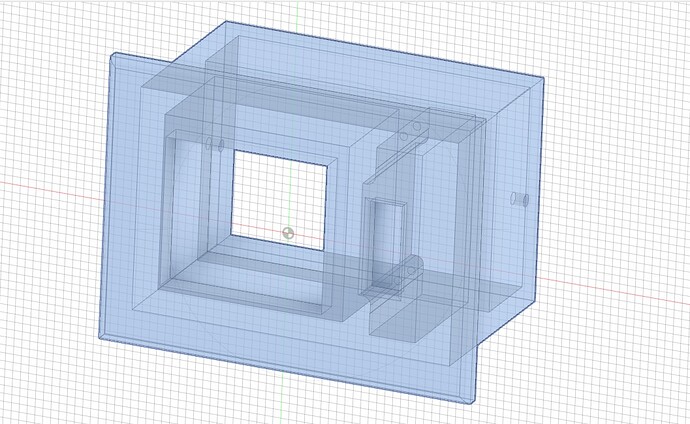

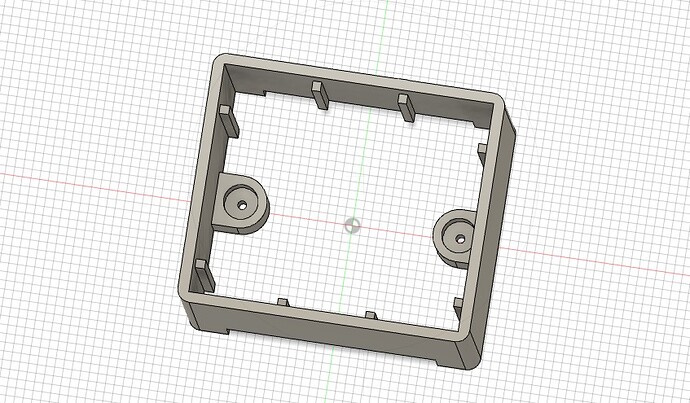

This depends on the functionality and material requirements. The current Hitachi elevator button housings I am prototyping (nearly finished), the building engineers plan to test the final prototype with users (maybe one or two buttons at first) in PLA-F first and if we are happy with the strength, I will print more in PLA-F. If not, then I will change to PETG+. However, before we "mass print" any prototype, we will unit-test first over a few weeks with the building engineers.

After we finish testing live with actual users, we will decide the next steps; but my guess is the building supervisor will ask me to print more in PLA-F, since they already like the prototypes and they are very strong as designed (to survive user abuse and vandalism).

The table-vise mount for my microphone boom was prototyped in PLA+ and I did the final print in PETG, and it is very strong and I have no plans to print it again anytime soon. PLA+ was great for prototyping, but it was too weak to handle the stress of a 30mm vise screw, even at a very high percentage of Cubic infill. PETG is much stronger compared to PLA. For these parts, I don't need metal or carbon-fiber. Maybe in the future if a requirement comes up and I design some parts for my motorcycle or cars; then I will decide what to do. I may just send the design to a machine shop and let them mill my CAD design in aluminum after prototyping in PLA.

In other words, there is no general answer to your question about materials because these parts are not for mass production. My current projects are for one building and the people driving the final product are the building engineers. They will tell me what the like and how good the designs and materials work. The want to save money, so I am guessing they will be happy with PLA.

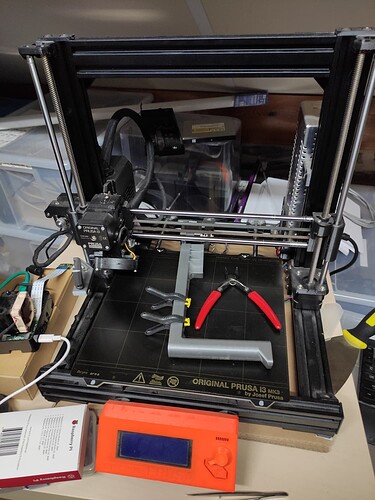

I have BLTouch already (in a box in my closet) but I am not going to install it anytime soon. I prefer manual leveling. When we manual level, we can get a feel for what is going on and so my recommendation is for all beginners to "buck the YT trend" and get passionate about manual bed leveling and CAD before considering adding trendy types of machine -leveling upgrades. You have probably noticed that a large majority of YT video are about "how to upgrade your printer" but I thing CAD design and prototyping are a much better use of time.

Regarding the build plate, as mentioned before, I don't have an issue with removing models from the print bed. so I'm not going to solve a problem that I don't have. I have plenty to do with my setup without resorting to doing printer upgrades to stay busy. I did order some "flexible build plate" a few weeks ago, but I cancelled the order and decided to stick with the great OOTB build plate which comes with the Ender 3v2. Frankly, I'm not much at following YT trends and upgrading perfectly working printers.

Frankly, I have looked many upgrades and the only upgrade I'm happy with so far is changing the print bed springs and leveling wheels. The Ender 3v2 works great OOTB and after watching many YT videos on "the best upgrades for your 3D printer" etc. I got bored quickly because most of the upgrades seemed not as useful as learning Fusion360. I have printed over 3KG so far and have had little problems with printing, except for the one day of down time a few days ago, which seemed to be based on clog which happened after I printed a big model with PETG. But to be frank, I don't have enough evidence to say with 100% accuracy what was the problem and it cleared itself after I ran a bunch of PLA though the extruder with failed prints; and then the problem cleared up "all by itself".

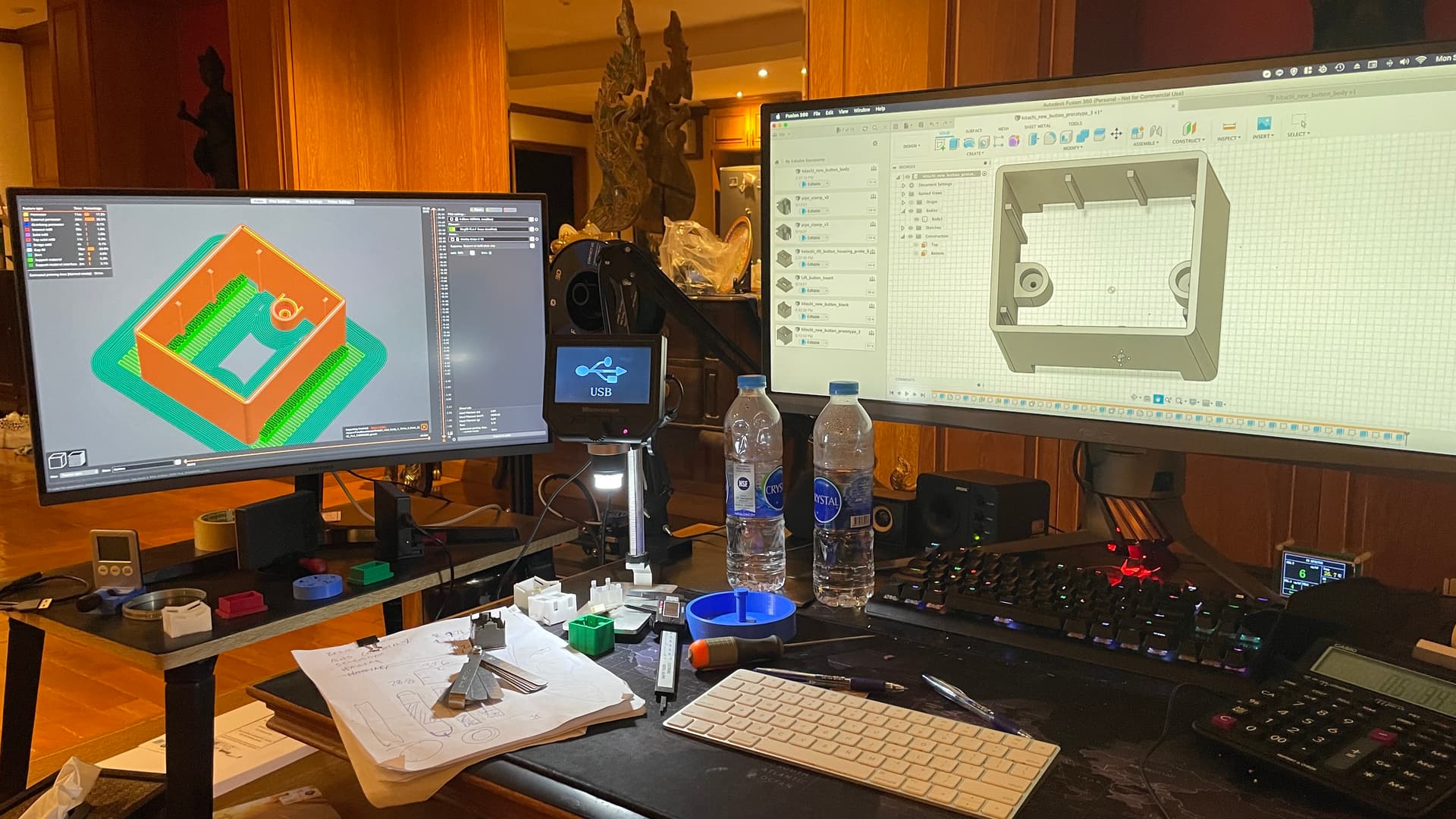

Also, there is a lot of buzz about adding the Raspberry PI to the printer, but I have my printer directly connected to my mac via USB cable, and it works fine. So this is another area where all the YT hype about adding a PI to the printer is not useful for me; as I have 64 GB mac with 12 cores attached to my printer

Thanks.

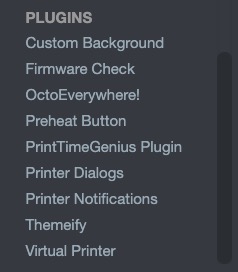

Well, IIWY, I would consider forking a Python plugin for OctoPrint and adding a new feature; and document all your steps, both success and failures - the chronicles of @SDohmen. You are interested in learning Python and OctoPrint is written in Python and writing plugins are a great way to learn a programming language. However, before you write your own plugin from scratch, I think it is best to fork and modify an existing plugin because most every plugin could use some feature enhancements. I noticed that many OctoPrint plugins I installed need new features and enhancements.

This is how I leaned Ruby, BTW. First, I modified some Discourse plugins. Then I wrote some Discourse plugins from scratch. Then I built an entire back-office application for a business who wanted to completely transform how their legacy app worked. The ROR project was huge and of course, when we come out of a project like that, our skills are quite strong in that language and style.

This is why I always recommend people learn coding by doing projects.

This is also why I recommend you @SDohmen fork a OctoPrint plugin and add new features to it. You will help out the community and you can document your progress step-by-step; and you will learn Python.

As a side note, I'm not knocking our forums, especially since I founded these forums decades ago; but personally, you might notice that I never ask coding questions on the net (in any form or forum). I think it is easy to read code, read the docs and write code without asking others to tell me what I can easily do myself from reading the docs and writing my own code (making mistakes and trying again until it works). There is so much code on the net, I find it's easier and much faster to just read code, write code, test code and repeat.

So, IIWY, since you want to learn Python, I would first fork a Python OctoPrint plugin you are interested in and add some new features. You will learn Python and you will gain experience with OctoPrint plugins and you can teach us all how you travelled from "zero to hero" with your first plugin remix.

Cheers.

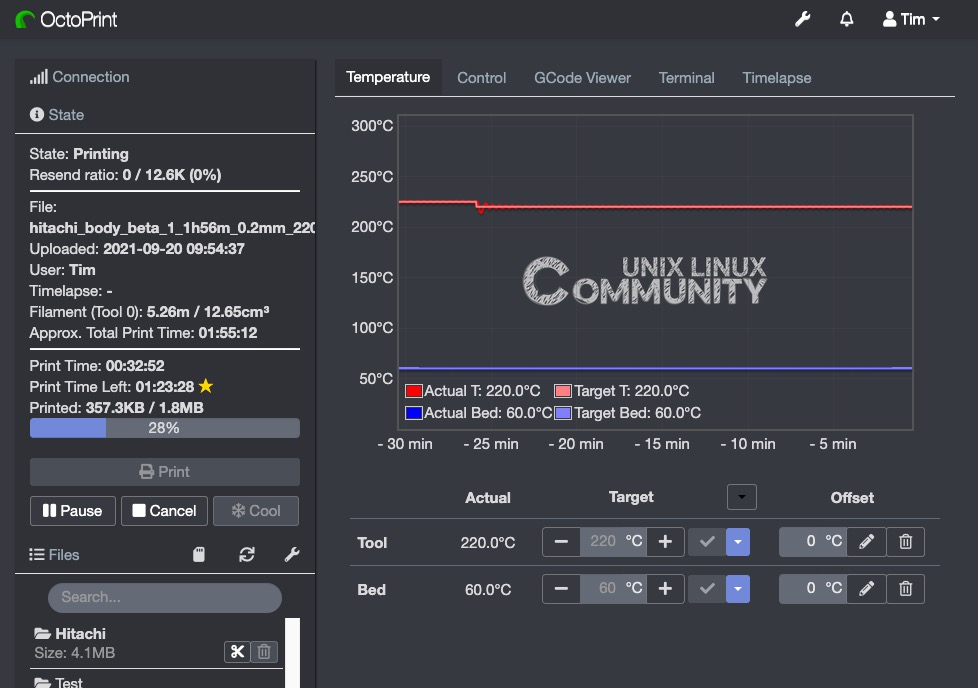

Note: If there was any change I could make today to the Ender 3v2 it would be to replace the micro USB port with a much more robust USB-A port. The Ender 3v2 micro USB port is very flimsy and easily disconnects and causes connection problems. I should also set up my Logitech web cam to remotely monitor the prints using OctoPrint.

![]()

.

.